基于UG NX在线检测与数据分析—原始数据通过测头在数控机床上取!

数控机床上安装测头可以实现在线检测、自动找正以及自动补偿和零件的尺寸公差控制,大大提高了数控机床的自动化程度,但其硬件和软件的匹配、价格因素、给编程人员增加了编程测头的工作量等因素制约着数控机床在线检测技术的应用和普及,但我认为随着软件和硬件的发展,编程人员需要掌握多种传感器的应用是趋势,不仅要在程序中考虑刀具的状态,还需要融入在线检测技术,视觉检测、三坐标检测等等,下面就说一下通过在线测头在数控机床上读取工件的点位数据,通过NX软件进行数据的分析,简单的替代了一下三坐标的功能,通过数据分析及在三坐标上实测,精度相差甚微,感觉在线检测的技术边界在向三坐标精密检测技术渗透。下面给一个我做的案例:

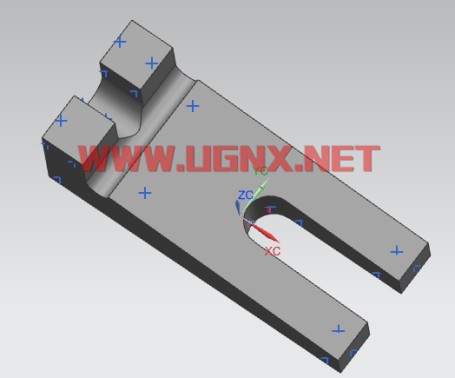

在数控机床上在线取点

在数控机床上在线取点

点导入到NX数模中

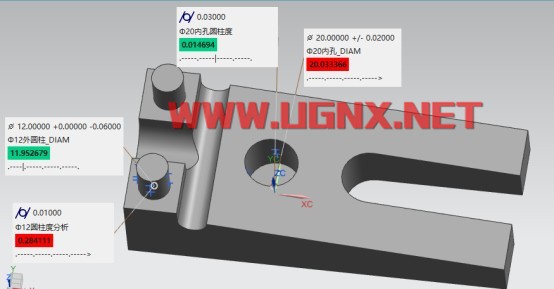

部分检测数据:

-----------------------------------------------------------

TOLERANCE SUMMARY

TOLERANCE NAME STATUS

PLANE1_FLAT FAIL

PLANE3_DISTB_1 FAIL

PLANE3_PARLEL FAIL

CYLINDER1_CIRLTY PASS

上表面平面度 PASS

====================================================================

TOLERANCE DETAIL

TOLERANCE TEXT FLT|0.01

TOLERANCE NAME PLANE1_FLAT

FEATURE NAME PLANE1

MAX DEVIATION 0.070983

STATUS FAIL

-------------------------------------------------------------------------

POINT DESIGN ACTUAL XFORMED DELTA DEVIATION

-------------------------------------------------------------------------

PT 4 0.035490

X 65.669800 65.669800 65.671787 0.001987

Y -30.000000 -30.018900 -30.035490 -0.035490

Z 8.000000 8.000000 7.999531 -0.000469

PT 5 -0.035491

X -56.699300 -56.699300 -56.699341 -0.000041

Y -30.000000 -29.201900 -29.964509 0.035491

Z 40.000000 40.000000 40.002125 0.002125

PT 6 -0.035491

X -65.481200 -65.481200 -65.479280 0.001920

Y -30.000000 -29.867900 -29.964509 0.035491

Z 8.000000 8.000000 7.994658 -0.005342

PT 7 0.035491

X -69.811300 -69.811300 -69.811300 -0.000000

Y -30.000000 -29.264900 -30.035491 -0.035491

Z 40.000000 40.000000 40.000000 0.000000

------------------------------------------

部分形位公差检测报告

在NX中进行形位公差分析

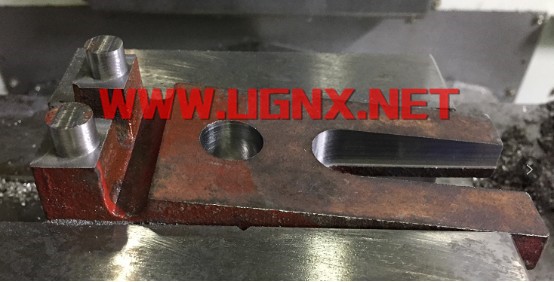

加工后再取点

加工外圆和内孔后取点

导入加工后测头检测的数据

分析一下数据;

TOLERANCE SUMMARY

TOLERANCE NAME STATUS

Φ12外圆柱_DIAM PASS

Φ12圆柱度分析 FAIL

Φ20内孔_DIAM FAIL

Φ20内孔圆柱度 PASS

====================================================================

TOLERANCE DETAIL

TOLERANCE TEXT DIAM 12.000000 +0.000000 -0.060000

TOLERANCE NAME Φ12外圆柱_DIAM

FEATURE NAME Φ12外圆柱

MIN DIAMETER 11.668568

MAX DIAMETER 12.236790

MID DIAMETER 11.952679

STATUS PASS

-------------------------------------------------------------------------

POINT DESIGN ACTUAL XFORMED DELTA DEVIATION

-------------------------------------------------------------------------

PT 1 0.010731

X -40.363419 -40.360200 -40.217567 0.145852

Y -13.283865 -13.253700 -13.288635 -0.004770

Z 42.168000 42.168000 42.157118 -0.010882

PT 2 -0.113083

X -46.512787 -46.508200 -46.375869 0.136918

Y -21.618371 -21.616400 -21.650588 -0.032217

Z 41.732000 41.732000 41.881764 0.149764

PT 3 0.014551

X -41.304013 -41.306200 -41.286135 0.017878

Y -13.257707 -13.214600 -13.242230 0.015477

Z 37.838000 37.838000 37.855797 0.017797

PT 4 0.003452

X -46.847125 -46.862400 -46.843543 0.003582

Y -20.595784 -20.599300 -20.626736 -0.030952

Z 37.729000 37.729000 37.892157 0.163157

PT 5 -0.151089

X -35.043565 -35.371400 -35.195435 -0.151870

Y -19.971723 -19.932000 -19.969045 0.002678

Z 43.424000 43.424000 43.259690 -0.164310

PT 6 -0.108985

X -46.397282 -46.432200 -46.284923 0.112359

Y -16.629056 -16.612100 -16.647171 -0.018115

Z 42.251000 42.251000 42.406835 0.155835

PT 7 0.010775

X -35.179516 -35.187100 -35.174773 0.004743

Y -20.706698 -20.704800 -20.732128 -0.025430

Z 37.665000 37.665000 37.496484 -0.168516

PT 8 0.020108

X -41.137371 -41.137100 -40.986834 0.150537

Y -25.248427 -25.236600 -25.271987 -0.023560

Z 42.446000 42.446000 42.436857 -0.009143

PT 9 0.030509

X -45.288900 -45.333700 -45.315532 -0.026632

Y -15.054128 -15.010300 -15.037724 0.016404

Z 37.717000 37.717000 37.846179 0.129179

PT 10 0.041859

X -41.241995 -41.242600 -41.220014 0.021981

Y -25.245118 -25.260100 -25.287899 -0.042781

Z 37.948000 37.948000 37.943633 -0.004367

出个检测报告:

上述的点数据完全是在数控机床上通过测头实际取的数据,NX负责读取点和分析数据及出检测报告,经和三坐标数据对比,精度比较理想

篇幅有限就不贴三坐标数据了,后面再探讨!

- 发表于 2020-08-21 15:32

- 阅读 ( 6684 )

- 分类:机械加工

你可能感兴趣的文章

- UG编程雷尼绍探头程序图文教程【附说明书和NX后处理】 34372 浏览

- 基于UG在线检测技术应用,经过测试雷尼绍和国产测头都可以哦! 9092 浏览